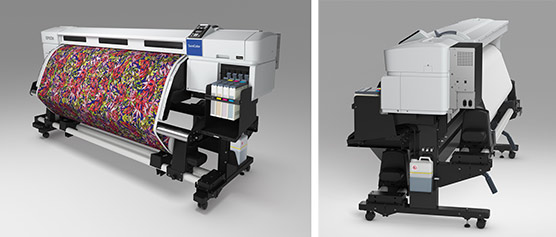

The SureColor Fabric DS series represent a revolution in dye sublimation. Designed from the ground up for sublimation, it provides an imaging platform for garments, sportswear, soft-signage and promotional items. Prints are made onto paper which is then transferred (sublimated) via a heat press onto material that contains a polyester base or has received a polyester pre-treatment. Unique to the Epson solution, the ink and hardware were developed together. This integrated approach has enabled exceptional print quality with outstanding productivity and enhanced mechanical durability. The system offers fast and flexible operation with low running costs, high reliability and easy management.

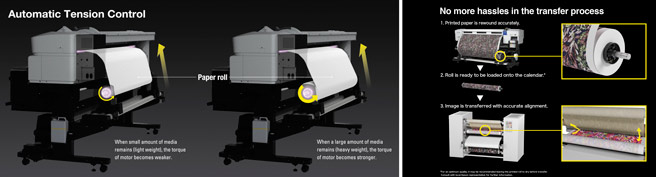

The SC-F7100 combines Epson's latest PrecisionCore™ print head with UltraChrome® DS ink, a Continuous Ink Supply System (CISS), a 64" print engine, Auto Tension Control (ATC), media output heater and a high precision Auto Take-Up. The head enables high resolution output with precise dot sizing, placement and ink density management. The ink supports a wide range of industry standard transfer media with output that is not only cost-effective but has predictable colour with a high dMax and extended Gamut. The engine and supply system facilitate continuous production at speeds up to 58.9m2/hr with sheet and roll based output. The media output heater ensures rapid drying while the ATC and ATU work together to ensure output rolls are compatible with high performance calendar style transfer equipment. The Auto Take-Up (ATU) ensures output rolls are compatible with high performance calendar style transfer equipment.

FEATURES AT A GLANCE

- High Productivity – supports sellable production speeds up to 30.4m2/hr with a 6L Continuous Ink Supply System, single operator roll based media loading, Automatic Tension Control, integrated output media heater and a high precision Auto Take-Up

- High Flexibility – supports media up to 64" (1625mm) wide and 1mm thick in rolls up to 40Kg

- Low Operational Cost – designed to minimise operator involvement, features low power consumption and uses cost-effective 1L ink refills

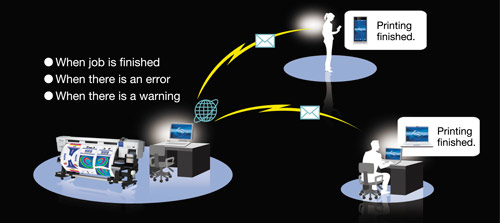

- Easy to Operate – can be loaded and managed by a single operator, features a large LCD control panel with in-built help, remote status notification and remote management, ships with an Ergosoft RIP customised for Epson complete with premium & professional features...Additional software compatibility Info

- Easy to Install – suits both commercial and office environments, does not require a special power supply, available with a choice of warranty options and has delivery costs included1

- Epson PrecisionCore™ (TFP) Print Head – supports up to 720x1440dpi resolution with Variable Sized Dot Technology™ (VSDT) for fine detail reproduction, consistent and solid colour, superior half tones and optimised ink consumption

- Epson UltraChrome™ DS ink – provides for consistent and predictable colour with a large gamut, wide media support & excellent image fastness

Quality Results with High Durability

The SureColor F7100 is built on a solid chassis that is assembled using robotic laser welding to support high production speeds with accurate tracking, minimum movement and noise. The printer incorporates Epson's latest PrecisionCore™ Thin Film Print (TFP) head with micro-fine nozzles for high resolution imaging with pin-point positional accuracy and outstanding uniformity. The head features Variable-Size Droplet Technology that enables superior image clarity with ultra-fine edges and improved half-tones. VSDT also enables precise ink density control for consistent and predictable colour with minimum consumption and cost.

Epson UltraChrome DS Ink was designed for production of a wide range of goods from material and clothing, to soft signage and banners, customised surface treatments and merchandise. It provides vibrant and intense colour that adheres quickly, transfers smoothly and provides excellent light and wash fastness. When used in conjunction with this printer, it produces superior output with lower production costs and enhanced mechanical durability. The ink is resistant to damage through abrasion and perspiration. When transfered to polyester fabrics it passes the Class 1 requirements of the Oeko-Tex Standard 100® enabling safe use by adults and children2. The ink supports a wide range of common transfer media including Epson's range of premium paper transfer paper which has been optimised to enable premium results.

Fast & Flexible Operation

The SureColor F7100 has been designed for fast and efficient roll to roll production. It supports media rolls up to 60% heavier than traditional, in a wide variety of thicknesses, weights and dimensions. It features a high performance media output dryer, Automatic Tension Control (ATC), and an Auto Take-Up (ATU) with precision tracking. Once a roll is printed it can be unloaded and mounted into a performance calendar-style transfer press for rapid high-volume production with outstanding quality.3

The F7100 has been designed for fast and cost-effective production with minimal maintenance and supervision. Media rolls of up to 40Kg in weight can be loaded and unloaded by a single operator. The printer features a continuous ink supply system with four large 1.5L tanks. The tanks incorporate sensors which warn in advance when ink is getting low. Refilling is a simple and quick process that can be undertaken while printing continues, using inexpensive 1L packs. The printer incorporates an e-mail system which can be configured to send status and error notifications to operators located on and/or off-site. The printer can be managed via the front panel LCD or remotely via supplied utility software. The engine features reduced power consumption with sleep and stand-by modes that help further reduce costs in environments that have a fluid workflow.

Easy to Install, Configure and Operate

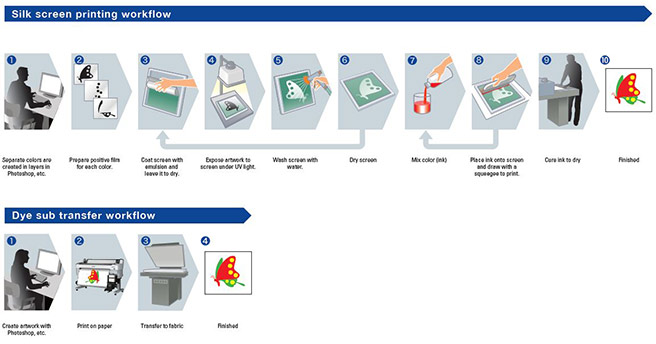

Dye sublimation offers significant benefits over traditional screen printing for fabric production. It is considerably quicker and less expensive for short to medium production runs, requiring less labour, set-up costs and wastage. Printing is mess free and production can occur in a relatively small amount of space. Job turnaround is faster and repeat runs can be undertaken at the push of a button. While prints can only be transferred (sublimated) onto fabric with a polyester base they can also be applied to other materials like metals, plastics and foam which will accept a polyester spray and withstand the heat and pressure of the transfer process. In this method items such as wall decorations, furniture finishes, phone covers and even footwear ('thongs') can be produced.

The SureColor Fabric series is delivered and installed through a process co-ordinated by Epson. The printer is configured on-site with utility software downloaded onto an operator's computer1. Printers are supplied with Ergosoft Sublimation RIP software that has been specially optimised for our models. The Epson edition contains a number of advanced features that are typically only available as options. The F7100 is supplied with a Professional Edition that includes additional Quality Control, Job Costing, Proofing, Hot-Folder and Production functionality.

1A PC with reasonable processing power, memory, storage, and networking facilities (with Web access) will be required. The independent sourcing of appropriate transfer equipment as well as external heater/ blower systems should be investigated. Delivery, installation and after-sales service is co-ordinated by Epson Australia in conjunction with our Authorised Reseller network. This service is provided free of charge conditional on factors including physical location and access. It does not cover any work &/or costs associated with connection to the electrical supply, building alterations and room refurbishments. Regional locations and installation environments which are not ground floor, have difficult access, and/or limited parking for delivery & set-up teams may attract additional charges. Installation and service may be restricted or limited when equipment is used outside of specification &/or with non-Epson consumables. Please contact Epson or one of our Authorised Resellers for full details on coverage, terms and limitations.

2The four colour Epson dye sublimation inks used in the Epson SureColor SCF7100/SC-F6000 series printers, when applied to polyester fabrics, pass the requirements of the Oeko-Tex Standard 100 for human ecological requirements of Class I products for adults, children, and babies up to 36 months. The standard specifies testing criteria for the presence of harmful substances within a textile product and belongs to the International Association for Research and Testing in the field of Textile Ecology (Oeko-Tex).

3ATC & ATU have been designed for optimum results at production speeds with limited performance in Draft mode. Operation at Draft mode, with heavy ink loads, with certain media types, and in environments with low temperature &/or high humidity may require the use of ancillary 3rd party heater/blower equipment.