Recycling Activities

As an integral part of our commitment to environmental conservation and advancing the circular economy, we actively collaborate with customers, communities and industry partners to collect and recycle end-of-life products.

Hardware Recycling

Epson Australia partners with ANZRP (Australia & New Zealand Recycling Program) who runs the TechCollect take-back service for electronic waste. The program offers a free service for the general public or small businesses to drop off their end-of-life printers, scanners and projectors for recycling responsibly.

Environmental Impact Snapshot

June 2022 – July 2023

BY RECYCLING ITS E-WASTE WITH TECHCOLLECT EPSON PREVENTED 2,580 TONNES IN CARBON EMISSIONS.

This is equivalent to planting 42,278 trees.1

BY RECYCLING ITS E-WASTE WITH TECHCOLLECT EPSON HELPED SAVE 256,101 M3 OF WATER.

This is equivalent to 6,676 days of household water use2.

BY RECYCLING ITS E-WASTE WITH TECHCOLLECT EPSON HELPED SAVE 33,895 GJ OF ENERGY.

This is equivalent of 100,144 days of household electricity consumption3.

Cartridge Recycling

Epson is a founding member of Cartridge for Planet Ark (C4PA) – an innovative program that provides printer users with an easy and environmentally accredited way to recycle used printer cartridges and consumables. Since inception of the C4PA program in 2003, Epson has recycled over 6 million units of ink cartridges avoiding over 255 tonnes of waste to landfill. A key innovative application of the recovered materials is a high-quality asphalt additive that is used to improve the durability of road surface in Australia.

Households and Small Businesses

Epson customers can drop off used printer cartridges and bottles at free of charge via the collection boxes located at participating retailers such as Officeworks, Australia Post, Harvey Norman, JB HiFi and The Good Guys stores.

Medium and Large Sized Businesses

Epson customers may be eligible to have a free C4PA collection box in your workplace if you can collect more than three (3) Epson cartridges, ink packs, bags and bottles in a month. You can also encourage your employees, customers or community to participate by bringing in their used cartridges from home to recycle. Together, we can help diverting used ink cartridges from landfill and turn them into other products.

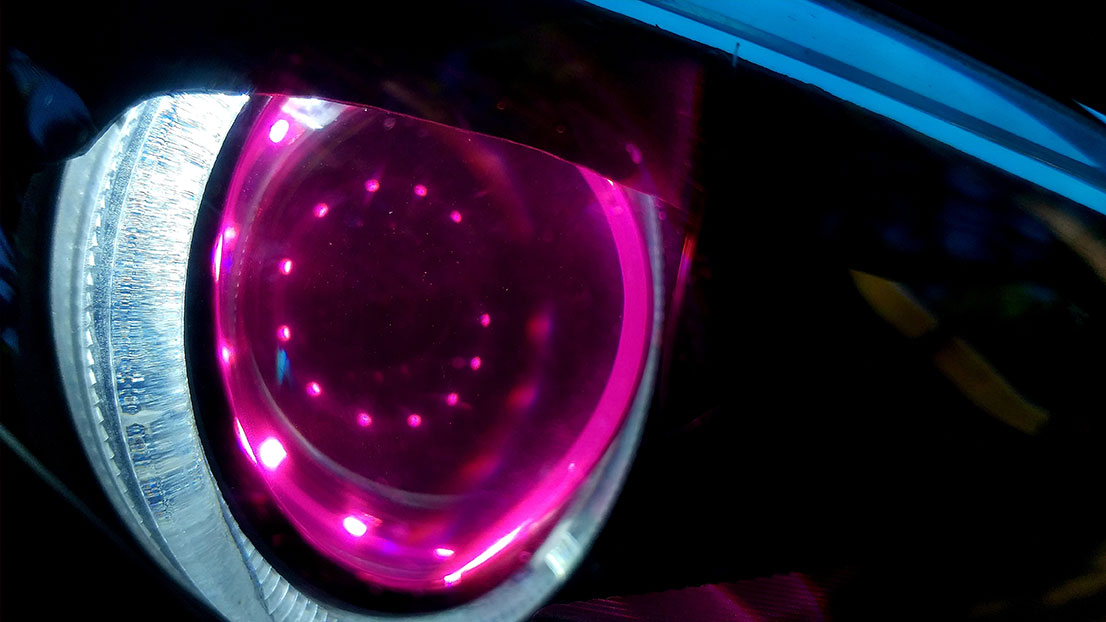

Projector Lamp Recycling

As part of its environmental leadership, Epson Australia has become the first IT vendor to offer a lamp recycling facility for old/broken projector lamps.

Consumers can return their old projector lamps – and not just Epson, but any brand – to one of Epson authorised service agents throughout Australia.

The lamps are sent to a recycling site where they are crushed and separated – environmentally sensitive chemicals are removed and other components are melted down for reuse.

To recycle your lamps:

Consumers: You can drop off your used projector lamps at any Epson's authorised Service Partner. All projector lamps regardless of manufacturer are accepted. To find your nearest collection point please call Epson Customer Service on 1300 361 054.

Epson's Authorised Service agents: Please follow the usual process that is in place for warranty parts returns by emailing warrantyrtns@epson.com.au including the number of cartons of faulty/unused parts and lamps, as well as the weight of each carton. We will then organise a courier pickup for the disposal or recycling of the parts and lamps.

Other businesses: Recycling is a collective effort. Thank you for playing a part in this. Please pack the used lamps in a carton and contact warrantyrtns@epson.com.au to organise a courier pickup. Provide your location, number of cartons, as well as the weight of each carton.

Find more information about how Seiko Epson is minimising waste and contributing to the formation of a circular economy.