Back catalogue – SureColor F9360 - 64"

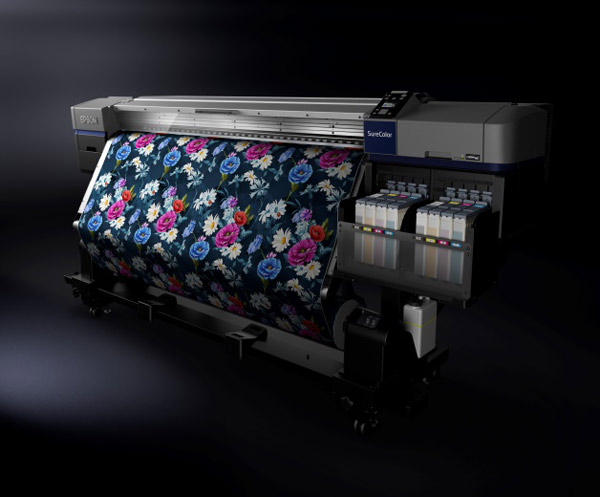

When the Epson SureColor Fabric DS series was first released it represented a revolution; designed from the ground up for Dye Sublimation, it provided a single-vendor turn-key solution with full factory warranty. The F9360 takes this further, incorporating the very latest imaging technology to enable production at outstanding speed with superior quality and an exceptional gamut.

The SC-F9360 combines the latest Epson Precision Dot Technology, with advanced media management, and UltraChrome DS HDk ink, to enable exceptionally high speed production with outstanding print quality. It achieves an exceptional gamut using just 4 colours and will print at speeds up to 109m2/hr. The 64" wide print engine is supported by a large Continuous Ink Supply System (CISS) and a high precision Auto Take-Up. It is simple to operate, ships complete with software, and its self-cleaning system ensures reliable operation with minimal maintenance. The printer is designed for soft signage and fabric production and can also be used for hard surface work.

FEATURES AT A GLANCE

FEATURES AT A GLANCE

- Superior Quality – DUAL Epson PrecisionCore™ (TFP) Print Heads support resolutions up to 720x1440dpi using Epson UltraChrome™ DS ink for precise, predictable and bright colour. Uses an HDk ink formulation and Epson Precision Dot Technology to achieve outstanding image quality with fine gradation and an exceptional gamut.

High Reliability – combines a proven production platform with an upgraded heater, platen and head carriage. Smooth and stable production is supported at the fastest speeds with integrated crash guards and dust collectors for worry-free operation. The printer is backed by a comprehensive warranty that can be augmented with up to FIVE YEARS CoverPlus protection1

High Reliability – combines a proven production platform with an upgraded heater, platen and head carriage. Smooth and stable production is supported at the fastest speeds with integrated crash guards and dust collectors for worry-free operation. The printer is backed by a comprehensive warranty that can be augmented with up to FIVE YEARS CoverPlus protection1 Excellent Flexibility – compatible with roll media from 12” to 64" (300-1626mm) wide in thicknesses from 0.04 to 1mm. Supports a wide range of quality requirements and material needs with standard modes for fabric and enhanced HQ modes for hard surface work.

Excellent Flexibility – compatible with roll media from 12” to 64" (300-1626mm) wide in thicknesses from 0.04 to 1mm. Supports a wide range of quality requirements and material needs with standard modes for fabric and enhanced HQ modes for hard surface work.- Outstanding Productivity – designed for production speeds of 18 to 60m2/hr, sellable output can be made at up to 93m2/hr. A large 12L Continuous Ink Supply System is matched with support for media rolls up to 45Kg and a high-precision Auto Take-Up for unattended roll-to-roll operation.

Reduced Cost – runs off a standard power supply, is relatively quick to install1, and is supplied complete with Epson Edge Print software (can also be ordered with an optional high-performance Ergosoft RIP). Operates with reduced power consumption and uses cost-effective 1L ink refills. Requires minimal maintenance and features a self-cleaning print head. Downloadable software enables easy expense tracking & job costing.

Reduced Cost – runs off a standard power supply, is relatively quick to install1, and is supplied complete with Epson Edge Print software (can also be ordered with an optional high-performance Ergosoft RIP). Operates with reduced power consumption and uses cost-effective 1L ink refills. Requires minimal maintenance and features a self-cleaning print head. Downloadable software enables easy expense tracking & job costing.

QUALITY RESULTS AT MAXIMUM SPEED

The SureColor F9360 features a strengthened chassis for accurate tracking at the fastest production speeds. Dual PrecisionCore Thin Film print heads facilitate high resolution imaging with pin-point accuracy and outstanding uniformity. Epson’s latest Precision Dot Technology has enabled significant improvement in gradation while also reducing graininess and banding at fast production speeds. An advanced new multi-part platen provides support for an enhanced range of media while upgraded print modes facilitate enhanced quality on fabric (Standard modes) as well as solid surfaces (HQ modes).

Epson UltraChrome DS Ink was designed to suit the production requirements of a wide range of goods from material and clothing, to soft signage and banners, customised surface treatments and merchandise. It provides vibrant and intense colour that adheres quickly, transfers smoothly and provides excellent light and wash fastness. It conforms to the AZO requirements and when applied to polyester fabrics it conforms to the latest Oeko-Tex Eco Passport® standard for safe use by adults, children and babies2. The F9360 was specifically designed to work with the advanced HDk version where, in conjunction with Precision Dot Technology, it enables gamut levels equivalent to competing product with 6 or more inks, using just 4 colours.

EFFICIENT WORKFLOW

The SureColor F9360 has been designed for efficient operation at high-speed. It incorporates an upgraded feed path with an active multi-point tracking and management system for quality imaging at the highest production speeds. The print heads are self-cleaning and mounted in a carriage unit that has an integrated crash guard and dust catcher. The printer incorporates a high-capacity Continuous Ink Supply System (CISS) that can be refilled while printing or pre-emptively ‘topped-up’ via a new ‘chip-n-replace’ facility. A high precision integrated Auto Take-Up (ATU) works together with advanced tracking and tension control to enable continuous unattended roll-to-roll production with consistent tension and parallelism. When used in conjunction with a calendar style heat press it can produce product of outstanding quality.

The SC-F9360 features a media loading system that can be managed by a single operator. It holds rolls up to 45Kg, in diameters up to 250mm, and thicknesses as little as 0.04mm. A simple and easy to use management utility, Epson Control Dashboard, enables media and profile information to be downloaded and made available for rapid selection. The same utility provides support for remote monitoring, management and reporting. An additional downloadable utility, the Epson LFP Accounting Tool, tracks costs and facilitates easy Job Costing.

EASY TO INSTALL & OPERATE

The SureColor F9360 requires minimal space to operate. It runs off a standard 240V power supply and can be driven by a moderately powered PC. The printer ships with new Epson Edge Print software that is easy to use and incorporates a high precision Adobe Postscript engine for quality imaging of PS, EPS, PDF, TIFF, JPEG and PNG files. Edge Print provides all the functionality required to preview and process images with basic functions such as copy, position, trim and nest, as well as advanced tiling, step and repeat. For performance users the printer can be also ordered with the latest V15 version of Ergosoft Sublimation in an advanced Production edition.

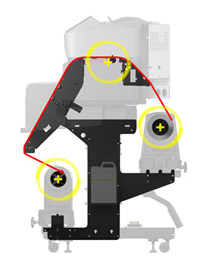

1Installation by a qualified engineer is strongly recommended and can be arranged with Epson either directly or through our Authorised Reseller Network. The independent sourcing of appropriate transfer equipment will be required and the use of an external heater/ blower system is generally recommended. After-sales service is co-ordinated by Epson in conjunction with our Authorised Reseller Network. Service may be restricted or limited when equipment is used outside of specification &/or with non-Epson consumables. For full details on coverage, terms and limitations please refer to our Warranty Statement.

2ECO PASSPORT by OEKO‐TEX® is an international standard for the textile industry system. It enables suppliers to demonstrate that products can be used in sustainable textile production. For further information please see the OEKO-TEX web site.

| SIZE | |||

|---|---|---|---|

| Max Media Width | 64 inch (1625.6mm) | ||

| PRINT TECHNOLOGY | |||

| Print Head | DUAL Epson PrecisionCore™ TFP | ||

| Print Modes | Uni & Bi-directional | ||

| Features | Variable Sized Droplet Technology (VSDT) Integrated Crash Guard and Dust Catcher Auto Nozzle Status Monitoring Auto Head Cleaning |

||

| Nozzle Configuration | 360 x 2 per colour | ||

| Active Channels | 2 x 4 | ||

| Maximum Resolution | 720 x 1440dpi | ||

| Min Droplet Size | 4pl | ||

| INK SYSTEM | |||

| Family | Epson Ultrachrome® DS | ||

| Type | Dye Sublimation | ||

| Colours | 2 x C / Y / M / HDk with extended Gamut & dMax | ||

| Supply | 8 x 1.5L Continuous Ink Supply System (CISS) | ||

| Refills | 1L packs (shipped in individual colour cartons of 6pcs) | ||

| PERFORMANCE | |||

| Draft | 360 x 720dpi (1 Pass) 108.6m2/hr | ||

| Standard Fast Production | 360 x 720dpi (1 Pass) 93.3m2/hr | ||

| Standard Production | 720 x 720dpi (2 Pass) 60.1m2/hr | ||

| Standard Quality Production | 720 x 720dpi (3 Pass) 44.1m2/hr | ||

| Standard Premium Production | 720 x 720dpi (4 Pass) 29.9m2/hr | ||

| HQ Fast Production | 720 x 720dpi (4 Pass) 25.4m2/hr | ||

| HQ Standard Production 2 | 720 x 1440dpi (6 Pass) 17.5m2/hr | ||

| HQ Premium Production 3 | 720 x 1440dpi (8 Pass) 13.5m2/hr | ||

| Figures represent print times only based on the test sample image as shown, produced on Epson Multi-Purpose DS Paper using Epson Edge Print. The total throughput time for a particular job will depend on a number of factors including the PC specification, RIP application, workflow configuration, networking, file format / size, image content, paper type, print mode, Auto-Take-Up activation and Heater activation. |  |

||

| MEDIA SUPPORT | |||

| Format | Single roll | ||

| Size | 300-1626mm wide x 250mm diameter, 2”/ 3" core | ||

| Thickness | 0.04 - 1.0mm | ||

| Min Margins | 3mm left & right (5mm when using Media Holding Plates) 5mm leading & trailing edges |

||

| Borderless Printing | Not Supported | ||

| Max Print Length | 600m (Subject to roll length & RIP s/w limitations) | ||

| Loading | Rear with integrated lifter & auto skew adjustment | ||

| Roll Handling | Media pre-set support Epson EMX profile support Print Length Tracking Advanced Auto Tension Control (Ad-ATC) |

||

| Output | Sheets (manual cutting) Roll to roll with integrated Auto Take-Up (ATU) - 914mm min roll width |

||

| OPERATION | |||

| Control Panel | 2.7” Colour LCD | ||

| Interface | High Speed USB 2.0 Ethernet 100Base-T/1000Base-T |

||

| Included Software (Windows) | Epson Edge Print, Epson Communications Driver, Epson Control Dashboard, EpsonNet Setup, EpsonNet Config, EpsonNet Print, Software Updater, Epson Manual Launcher, Operators Guide & General Guide | ||

| Web Downloads (Windows) | LFP Accounting Tool | ||

| Included Software (Mac) | N/A | ||

| Web Downloads (Mac) | Epson Control Dashboard, EpsonNet Setup, EpsonNet Config, Software Updater, Software Updater, Epson Manual Launcher, Operators Guide & General Guide | ||

| OS Compatibility |

Mac OS X 10.6.8 or later |

||

|

Compatible with a wide range of design, production, workflow management, and RIP software |

|||

| Memory | 512 MB Main + 128MB Network | ||

| Language | ESC/P Raster | ||

| ENVIRONMENTAL | |||

| Operational Temp | 15°-25° | ||

| Operational Humidity | 40 to 60% with no condensation | ||

| Power Supply | 2 x 5A, 240V, 50/60 Hz AC | ||

| Power Consumption | 570W Operating / Standby 340W / 14W Sleep (1000BASE-T) | ||

| Operating Noise | 54dB | ||

| Operational Space (W x D x H) | 3620 x 2934 x 1770mm recommended | ||

| PHYSICAL | |||

| Dimensions (W x D x H) |

2620 x 934 x 1332mm (when stored) |

||

| Weight | 290Kg (without ink) | ||

| WHAT'S IN THE BOX | |||

|

Printer, Media Supply System (MSS), Continuous Ink Supply System (CISS), 1 x 64” Roll of Epson Multi- Purpose Transfer Media, 1 x Maintenance Kit, 1 x Carriage Rod Grease Kit, Set-up guide, Epson Edge Print Software (CD), Operator Guide & Utility software (CD). Some configurations also include Ergosoft RIP Software (Epson Edition). Important: No ink is included with the printer; 2 x KDk starter Packs should be ordered separately. An appropriate heat press will need to be sourced separately and an ancilliary heater unit is recommended for high speed operation. |

|||

| SYSTEM REQUIREMENTS | |||

| A Personal Computer will be required for installation and operation of this printing system. The PC should have a minimum Intel Core i3 /AMD Phenom 2 or equivalent processor (2.5Ghz i5 or greater with separate GPU recommended), 8GB or more memory, a 250GB or larger HDD (1TB recommended), running Windows Vista 32bit or greater (Win 7 64bit/Win 8 recommended). A DVD drive with +/-RW read support and a network with external Web access will be required for installation. For optimum performance it is recommended that 1000Base-T Ethernet networking be employed. High speed web access and an off-line storage facility with DVD+/-RW write support is recommended for operation with the ErgoSoft RIP. The use of a 3rd party ancillary heater/ blower unit is highly recommended with this machine. The typical operational environment will also involve a calendar style heat press. Please speak with your dealer for recommendations. |

|||

|

Packaging |

Printer: 3170 x 1100 x 1111mm, 400Kg |

||

| CONFIGURATION OPTIONS | |||

| SCF93601YR | Printer with 1Yr Warranty | ||

| SCF93603YR | Printer with 3Yr CoverPlus** | ||

| SCF93605YR | Printer with 5Yr CoverPlus** | ||

| SCF9360PRO1YR | Printer + Ergosoft V15 Production and 1Yr Warranty** | ||

| SCF9360PRO3YR | Printer + Ergosoft V15 Production and 3Yr CoverPlus** | ||

| SCF9360PRO5YR | Printer + Ergosoft V15 Production and 5Yr CoverPlus** | ||

| ACCESSORIES & OPTIONS | |||

| C12C932111 | HDk Starter Ink Pack – 4 Colour x 1L | ||

| 1YWF9360 | 1Yr CoverPlus On-Site Service Pack** | ||

| 2YWF9360 | 2Yr CoverPlus On-Site Service Pack** | ||

| SERVICE & SUPPORT | |||

|

** The printer comes with a comprehensive 1 year warranty that includes cover for the Print Heads but excludes the CISS (3 month replacement warranty). CoverPlus increases the service response level, adds full cover for the CISS, and extends total cover by an additional 1, 2, 3, or 4 years (multiple packs can be combined). CoverPlus can be purchased concurrently with the printer or ordered separately up to 365 days after the original invoice date. Limitations apply to the provision of Warranty and CoverPlus. Support is only provided for product supplied through Epson Australia or Epson New Zealand. The facility is provided in conjunction with the Authorised Large Format Reseller through which the product is ordered. Regional locations and installations with difficult access may attract additional charges. Service may be restricted or limited when equipment is modified, used outside of specification, &/or with non-Epson consumables. For full details on coverage, terms and limitations please review the warranty terms listed on this web-site and contact Epson or one of our Authorised Large Format Resellers if you have questions or concerns.. |

|||

| SIZE | |||

|---|---|---|---|

| Max Media Width | 64 inch (1625.6mm) | ||

| PRINT TECHNOLOGY | |||

| Print Head | DUAL Epson PrecisionCore™ TFP | ||

| Print Modes | Uni & Bi-directional | ||

| Features | Variable Sized Droplet Technology (VSDT) Integrated Crash Guard and Dust Catcher Auto Nozzle Status Monitoring Auto Head Cleaning |

||

| Nozzle Configuration | 360 x 2 per colour | ||

| Active Channels | 2 x 4 | ||

| Maximum Resolution | 720 x 1440dpi | ||

| Min Droplet Size | 4pl | ||

| INK SYSTEM | |||

| Family | Epson Ultrachrome® DS | ||

| Type | Dye Sublimation | ||

| Colours | 2 x C / Y / M / HDk with extended Gamut & dMax | ||

| Supply | 8 x 1.5L Continuous Ink Supply System (CISS) | ||

| Refills | 1L packs (shipped in individual colour cartons of 6pcs) | ||

| PERFORMANCE | |||

| Draft | 360 x 720dpi (1 Pass) 108.6m2/hr | ||

| Standard Fast Production | 360 x 720dpi (1 Pass) 93.3m2/hr | ||

| Standard Production | 720 x 720dpi (2 Pass) 60.1m2/hr | ||

| Standard Quality Production | 720 x 720dpi (3 Pass) 44.1m2/hr | ||

| Standard Premium Production | 720 x 720dpi (4 Pass) 29.9m2/hr | ||

| HQ Fast Production | 720 x 720dpi (4 Pass) 25.4m2/hr | ||

| HQ Standard Production 2 | 720 x 1440dpi (6 Pass) 17.5m2/hr | ||

| HQ Premium Production 3 | 720 x 1440dpi (8 Pass) 13.5m2/hr | ||

| Figures represent print times only based on the test sample image as shown, produced on Epson Multi-Purpose DS Paper using Epson Edge Print. The total throughput time for a particular job will depend on a number of factors including the PC specification, RIP application, workflow configuration, networking, file format / size, image content, paper type, print mode, Auto-Take-Up activation and Heater activation. |  |

||

| MEDIA SUPPORT | |||

| Format | Single roll | ||

| Size | 300-1626mm wide x 250mm diameter, 2”/ 3" core | ||

| Thickness | 0.04 - 1.0mm | ||

| Min Margins | 3mm left & right (5mm when using Media Holding Plates) 5mm leading & trailing edges |

||

| Borderless Printing | Not Supported | ||

| Max Print Length | 600m (Subject to roll length & RIP s/w limitations) | ||

| Loading | Rear with integrated lifter & auto skew adjustment | ||

| Roll Handling | Media pre-set support Epson EMX profile support Print Length Tracking Advanced Auto Tension Control (Ad-ATC) |

||

| Output | Sheets (manual cutting) Roll to roll with integrated Auto Take-Up (ATU) - 914mm min roll width |

||

| OPERATION | |||

| Control Panel | 2.7” Colour LCD | ||

| Interface | High Speed USB 2.0 Ethernet 100Base-T/1000Base-T |

||

| Included Software (Windows) | Epson Edge Print, Epson Communications Driver, Epson Control Dashboard, EpsonNet Setup, EpsonNet Config, EpsonNet Print, Software Updater, Epson Manual Launcher, Operators Guide & General Guide | ||

| Web Downloads (Windows) | LFP Accounting Tool | ||

| Included Software (Mac) | N/A | ||

| Web Downloads (Mac) | Epson Control Dashboard, EpsonNet Setup, EpsonNet Config, Software Updater, Software Updater, Epson Manual Launcher, Operators Guide & General Guide | ||

| OS Compatibility |

Mac OS X 10.6.8 or later |

||

|

Compatible with a wide range of design, production, workflow management, and RIP software |

|||

| Memory | 512 MB Main + 128MB Network | ||

| Language | ESC/P Raster | ||

| ENVIRONMENTAL | |||

| Operational Temp | 15°-25° | ||

| Operational Humidity | 40 to 60% with no condensation | ||

| Power Supply | 2 x 5A, 240V, 50/60 Hz AC | ||

| Power Consumption | 570W Operating / Standby 340W / 14W Sleep (1000BASE-T) | ||

| Operating Noise | 54dB | ||

| Operational Space (W x D x H) | 3620 x 2934 x 1770mm recommended | ||

| PHYSICAL | |||

| Dimensions (W x D x H) |

2620 x 934 x 1332mm (when stored) |

||

| Weight | 290Kg (without ink) | ||

| WHAT'S IN THE BOX | |||

|

Printer, Media Supply System (MSS), Continuous Ink Supply System (CISS), 1 x 64” Roll of Epson Multi- Purpose Transfer Media, 1 x Maintenance Kit, 1 x Carriage Rod Grease Kit, Set-up guide, Epson Edge Print Software (CD), Operator Guide & Utility software (CD). Some configurations also include Ergosoft RIP Software (Epson Edition). Important: No ink is included with the printer; 2 x KDk starter Packs should be ordered separately. An appropriate heat press will need to be sourced separately and an ancilliary heater unit is recommended for high speed operation. |

|||

| SYSTEM REQUIREMENTS | |||

| A Personal Computer will be required for installation and operation of this printing system. The PC should have a minimum Intel Core i3 /AMD Phenom 2 or equivalent processor (2.5Ghz i5 or greater with separate GPU recommended), 8GB or more memory, a 250GB or larger HDD (1TB recommended), running Windows Vista 32bit or greater (Win 7 64bit/Win 8 recommended). A DVD drive with +/-RW read support and a network with external Web access will be required for installation. For optimum performance it is recommended that 1000Base-T Ethernet networking be employed. High speed web access and an off-line storage facility with DVD+/-RW write support is recommended for operation with the ErgoSoft RIP. The use of a 3rd party ancillary heater/ blower unit is highly recommended with this machine. The typical operational environment will also involve a calendar style heat press. Please speak with your dealer for recommendations. |

|||

|

Packaging |

Printer: 3170 x 1100 x 1111mm, 400Kg |

||

| CONFIGURATION OPTIONS | |||

| SCF93601YR | Printer with 1Yr Warranty | ||

| SCF93603YR | Printer with 3Yr CoverPlus** | ||

| SCF93605YR | Printer with 5Yr CoverPlus** | ||

| SCF9360PRO1YR | Printer + Ergosoft V15 Production and 1Yr Warranty** | ||

| SCF9360PRO3YR | Printer + Ergosoft V15 Production and 3Yr CoverPlus** | ||

| SCF9360PRO5YR | Printer + Ergosoft V15 Production and 5Yr CoverPlus** | ||

| ACCESSORIES & OPTIONS | |||

| C12C932111 | HDk Starter Ink Pack – 4 Colour x 1L | ||

| 1YWF9360 | 1Yr CoverPlus On-Site Service Pack** | ||

| 2YWF9360 | 2Yr CoverPlus On-Site Service Pack** | ||

| SERVICE & SUPPORT | |||

|

** The printer comes with a comprehensive 1 year warranty that includes cover for the Print Heads but excludes the CISS (3 month replacement warranty). CoverPlus increases the service response level, adds full cover for the CISS, and extends total cover by an additional 1, 2, 3, or 4 years (multiple packs can be combined). CoverPlus can be purchased concurrently with the printer or ordered separately up to 365 days after the original invoice date. Limitations apply to the provision of Warranty and CoverPlus. Support is only provided for product supplied through Epson Australia or Epson New Zealand. The facility is provided in conjunction with the Authorised Large Format Reseller through which the product is ordered. Regional locations and installations with difficult access may attract additional charges. Service may be restricted or limited when equipment is modified, used outside of specification, &/or with non-Epson consumables. For full details on coverage, terms and limitations please review the warranty terms listed on this web-site and contact Epson or one of our Authorised Large Format Resellers if you have questions or concerns.. |

|||

View or Download additional information

Find drivers, manuals and product setup for SureColor F9360 - 64".

Go to Driver DownloadsFind important information about ink cartridge composition, precautions for safe handling and use, regulatory considerations and more.

Go to Material Safety Data SheetsAccess the drivers, utilities, and manuals for Epson point of sales and label printer products such as TM printers (TM series), customer displays (DM series), embedded unit printers and kiosk printer mechanisms.

Epson Downloads for POS Printers

GoEpson Downloads for ColorWorks Label Printers

GoContact support or service